In my freshmen year I designed and manufactured the carbon fiber body parts for 2012 Illini Hybrid Racing.

the body team was only me, plus two freshmen in aerospace engineering and electrical engineering.

It was a real learning experience for me as a freshmen in electrical engineering to get to practice with CAD software and carbon fiber manufacture methods.

Below are videos and pictures for the project

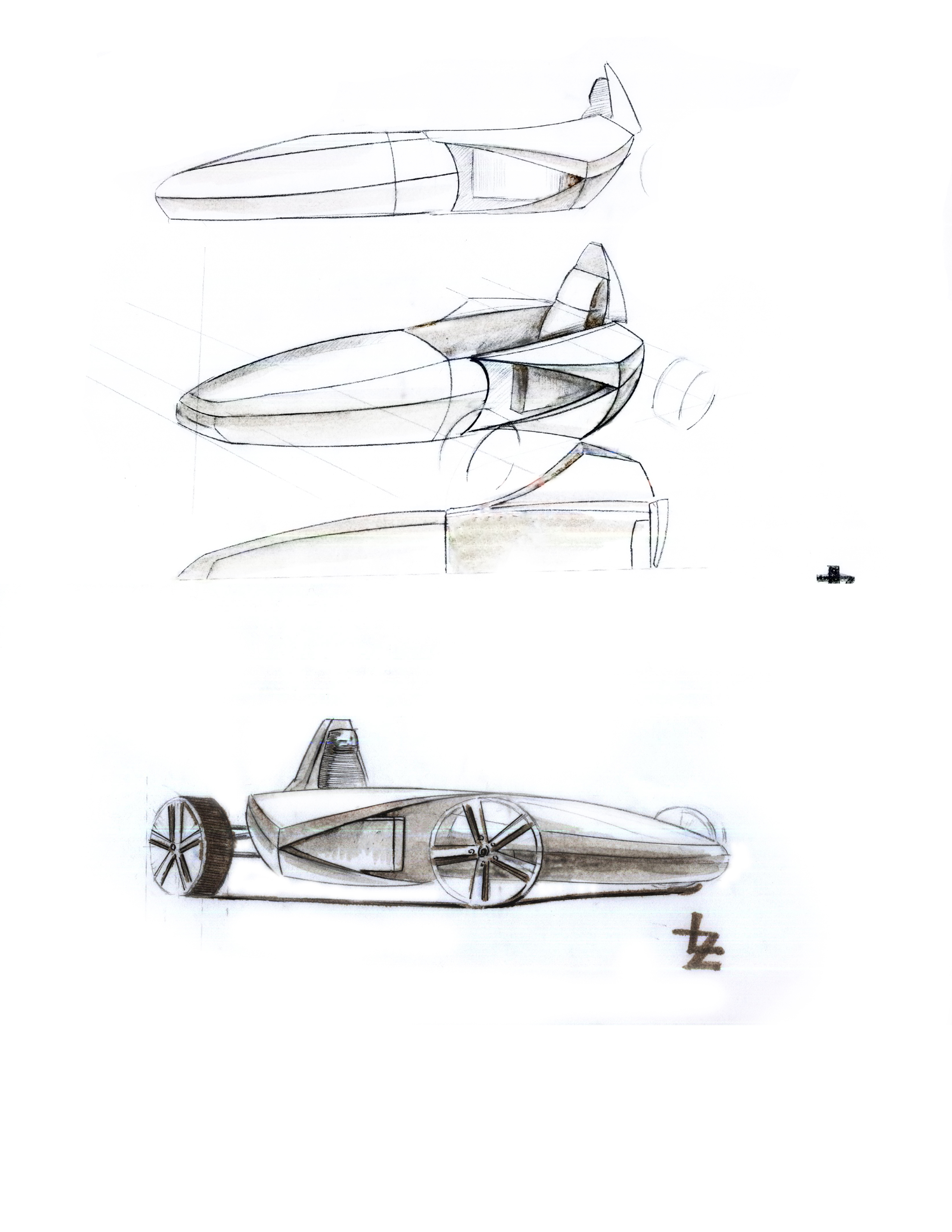

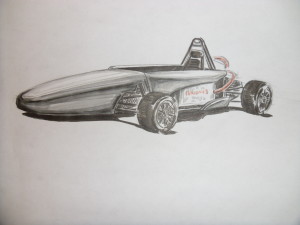

Body conceptual sketching

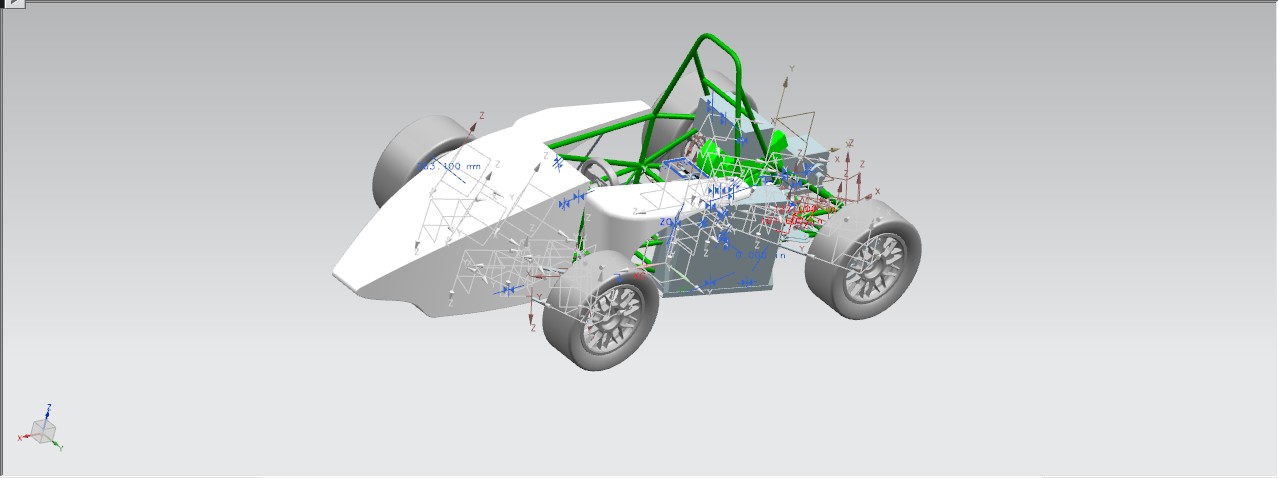

Designed nosecone and side pods using CAD and digital rendering software including Solidworks, NX(unigraphics), Corel Painter and Photoshop.

Worked in Composite Material Lab. learned VARTM vacuum bagging system to make carbon fiber parts, including 3 floor panels and 2 side covers. Worked with chassis team installing side cover and floor panel to the chassis.

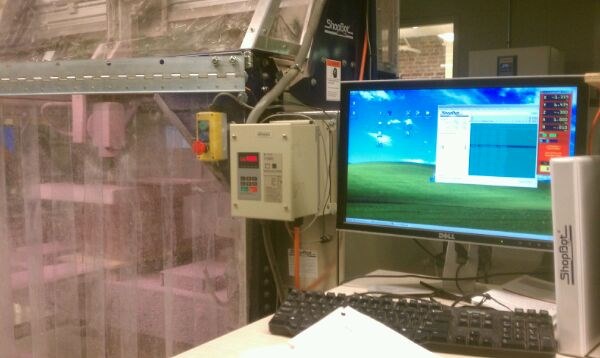

Worked on Shopbot 5-axis cnc mill, making male mold for the nosecone.

Designed painting pattern for the nosecone, made sponsors’ stickers and arranged them on the nosecone.

Traveled with team to Loudon, New Hampshire for International Formula Hybrid Competition.